POURING AUTOMATSPouring Automats manufactured by Intermetal allow continuous pouring of gray and spheroidal cast iron on all kinds of moulding plants within the cycle times. Our fully developed technique using tilting pouring ladles and ladles with tundish rod which ensures exact regulation of the molten iron flow and quantity. The iron stream is controlled by means of optical sensors and cameras, and a programmable regulating system matches the pouring speed to the mould consumption rate and ensures a precise pouring of castings of any kind and application. Technical data for pouring automats:

Technical data for pouring automats with tundish rod:

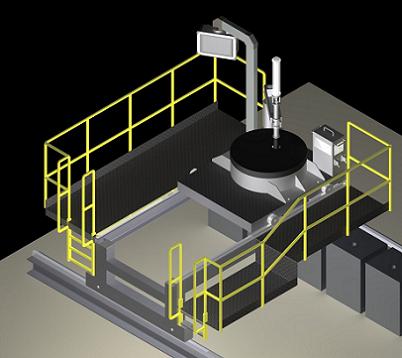

The pouring machine is constructed as mobile pouring carriage travelling on rails installed along the whole length of the pouring zone. The machine is normally equipped with automatic system for setting the pouring position based on the sprue cup location and on position of ladle exchange roller tracks. The control of the machine is performed by the operator from the cabin on the carriage. The pouring is controlled by the operator using lever proportional hydraulic controllers. The ladle exchange is done by charging and discharging roller conveyor. The ladle is designed to be set in tilting frame of the pouring machine. The ladle manipulation is performed by fork lift truck. The bottom of the ladle is fitted with necessary profiles for easy fork access. The ladle can be provided with rotary suspension with gearbox for tilting and crane manipulation outside the pouring machine.

Technical data for pouring semi-automats:

|

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

©Copyright: Intermetal Proizvodnja strojev in livarske opreme d.o.o. |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||